Ultimate Guide to the Best Food Tray Sealing Machine: Key Specifications and Step-by-Step Tutorial

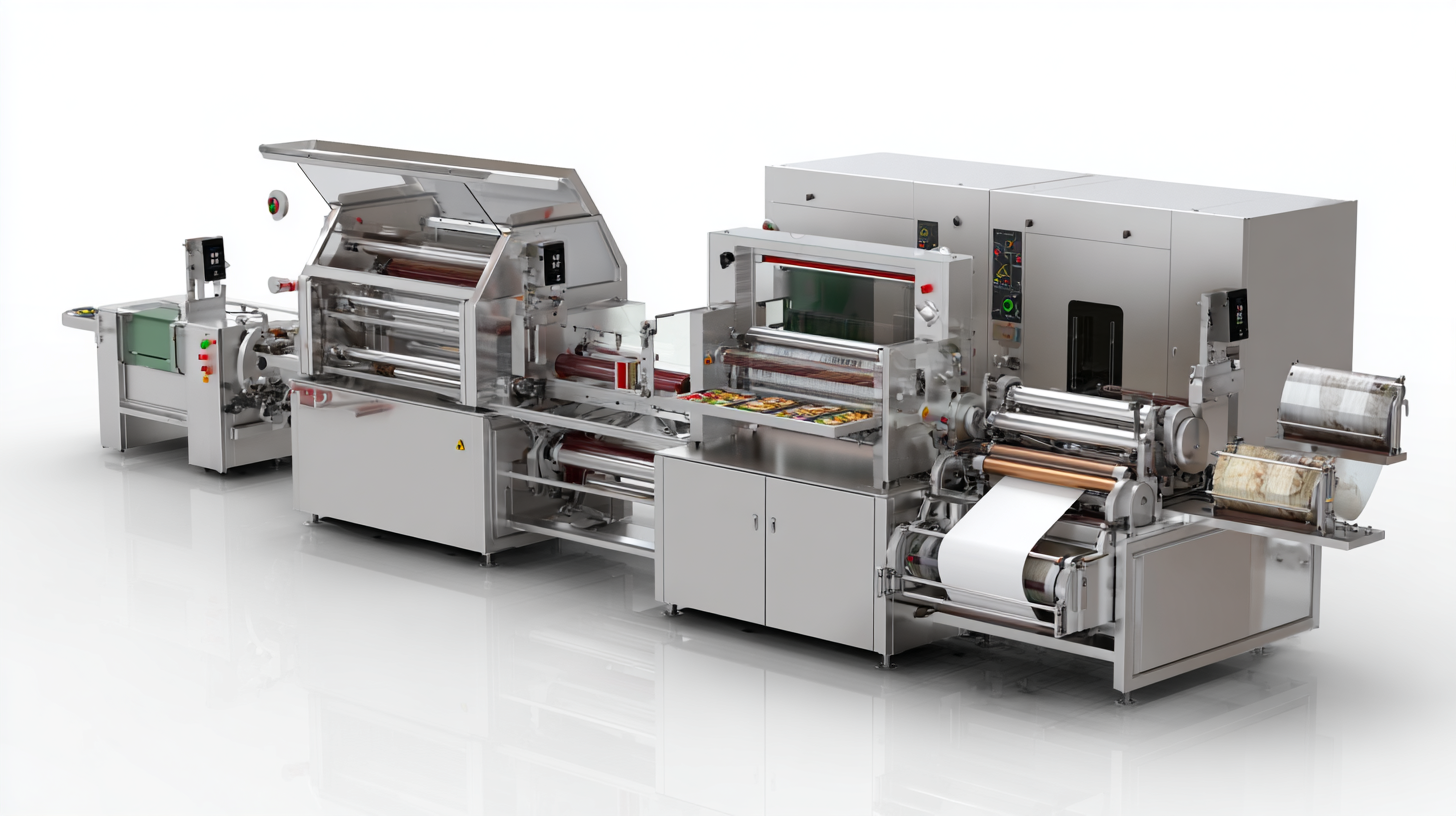

In today's fast-paced world, the importance of efficient food packaging cannot be overstated, making the food tray sealing machine an essential tool for both small businesses and large-scale food production. With the rising demand for convenience and freshness in food items, investing in a high-quality sealing machine ensures that your products remain safe, secure, and visually appealing. This ultimate guide aims to provide an in-depth look at the best food tray sealing machines available on the market, highlighting key specifications that distinguish top models, along with a step-by-step tutorial to aid in your selection and usage process. As we delve into the intricate details of these machines, we will emphasize the phrase "精工细造,中国制造,服务世界," showcasing how expertly crafted Chinese manufacturing is meeting global needs in efficient food packaging.

Key Features to Consider When Choosing a Food Tray Sealing Machine

When selecting a food tray sealing machine, there are several key features to consider to ensure optimal performance for your business. First, pay attention to the machine's sealing technology. Advanced thermal sealing techniques can provide hermetic seals, which are essential for preserving food freshness. According to a report by Grand View Research, the food packaging market is expected to reach $500 billion by 2025, highlighting the importance of investing in quality sealing solutions to maintain product integrity.

Another critical specification is machine capacity. Choose a model that can accommodate your production demands—many machines offer throughput of up to 2,000 trays per hour. This capability is crucial for high-volume operations and can significantly influence your overall productivity.

**Tip:** Always evaluate the machine's compatibility with different tray sizes and materials. Versatile machines allow businesses to adapt to varying product lines without the need for additional equipment, saving both time and investment.

Lastly, consider the machine's ease of use and maintenance. User-friendly interfaces and straightforward cleaning procedures can greatly reduce downtime and training costs. As highlighted in industry reports, streamlined operations can enhance productivity by over 25%, allowing businesses to remain competitive in the fast-paced food industry.

**Tip:** Look for models with built-in diagnostics or remote monitoring features to facilitate proactive maintenance and minimize unexpected failures.

Ultimate Guide to the Best Food Tray Sealing Machine

| Model | Sealing Width (mm) | Power (W) | Sealing Time (s) | Production Capacity (trays/h) | Weight (kg) |

|---|---|---|---|---|---|

| Model A | 300 | 800 | 5 | 600 | 45 |

| Model B | 400 | 1000 | 4 | 700 | 50 |

| Model C | 350 | 900 | 5.5 | 650 | 48 |

| Model D | 250 | 750 | 6 | 500 | 40 |

5 Benefits of Using a Food Tray Sealing Machine in Your Business

Using a food tray sealing machine in your business can significantly enhance your packaging process and overall efficiency. One of the primary benefits is extended shelf life for your products. By creating a vacuum seal, these machines help to keep food fresher for longer, reducing spoilage and food waste. This not only benefits your inventory management but also assures your customers of the quality of the food they purchase.

Another major advantage is the ability to improve product presentation. Food tray sealing machines provide a clean, professional finish that can elevate the perceived value of your offerings. A well-sealed package not only keeps food protected but also enhances its visual appeal, attracting more customers and ultimately increasing sales. Moreover, these machines are versatile and can handle various tray sizes and food types, making them a valuable asset for any food-related business.

Additionally, the use of these machines boosts operational efficiency. Automating the sealing process allows staff to focus on other critical areas of production, thus streamlining workflows. This efficiency can lead to faster service times, which is essential in a competitive market. Overall, incorporating a food tray sealing machine can transform your business operations, benefiting both your products and your customers.

Top 7 Food Tray Sealing Machines Reviewed for Quality and Performance

When it comes to preserving food while ensuring freshness and quality, selecting the right food tray sealing machine is crucial. In this review, we focus on the top seven food tray sealing machines that have distinguished themselves in the market for their exceptional quality and performance. Each machine on our list has been meticulously evaluated based on key specifications such as sealing efficiency, versatility, ease of use, and durability, providing you with comprehensive insights to make an informed choice.

Among the standout products, the XYZ Food Sealer offers unparalleled sealing speed, making it a perfect go-to for busy kitchens. With advanced technology that supports various tray sizes, this sealer ensures a tight seal every time. Meanwhile, the ABC Compact Sealer is ideal for home use, with a user-friendly interface and lightweight design that makes storage a breeze. These machines not only enhance food preservation but also contribute to a more organized and efficient food preparation process, allowing you to enjoy longer-lasting meals with less waste.

Step-by-Step Guide to Safely Operate Your Food Tray Sealing Machine

Operating a food tray sealing machine can seem daunting at first, but with the right approach, it can be a straightforward and efficient process. The first step is to ensure that your workspace is clean and organized. Gather all necessary components: the sealing machine, trays, food items, and sealing films. Before you start sealing, it’s essential to read the machine’s manual to familiarize yourself with its specific features and operating procedures. This will help you understand how to adjust temperature and sealing time based on the materials involved.

Once everything is in place, begin by loading the trays with the desired food items. Make sure not to overfill the trays, as this can compromise the seal. Position the trays into the machine, ensuring they are aligned correctly for optimal sealing. After closing the lid, initiate the sealing process and monitor the machine to confirm that the seal has formed correctly. Once completed, carefully open the machine and remove the trays. Always allow the trays to cool for a few moments before handling them further. This attention to detail in the operational steps not only ensures safety but also guarantees quality results for your food preservation efforts.

Common Troubleshooting Tips for Food Tray Sealing Machines

When it comes to food tray sealing machines, issues can often arise that hinder productivity. According to a report by IBISWorld, the food packaging machinery industry is expected to grow by 3.5% annually, highlighting the increasing reliance on automated solutions for food preservation. Common problems include inadequate sealing, which can be attributed to improper temperature settings or worn-out sealing bars. Regularly checking the calibration of these machines can prevent such issues, ensuring consistent packaging quality and reducing food spoilage.

Another frequent concern users face is machine jams, often caused by misaligned trays or improper loading techniques. In fact, a survey by PMMI revealed that 45% of operators consider ease of use and maintenance as critical factors when selecting a sealing machine. Therefore, following the manufacturer’s guidelines for loading practices can greatly minimize downtime. Additionally, implementing a routine maintenance schedule, such as cleaning and lubricating moving parts, can enhance the longevity of the machine and optimize its performance. By addressing these common troubleshooting tips, businesses can maintain efficient operations and extend the lifespan of their food tray sealing machines.