Real World Applications of Best Heat Sealing Machine and Challenges Faced in Packaging Industry

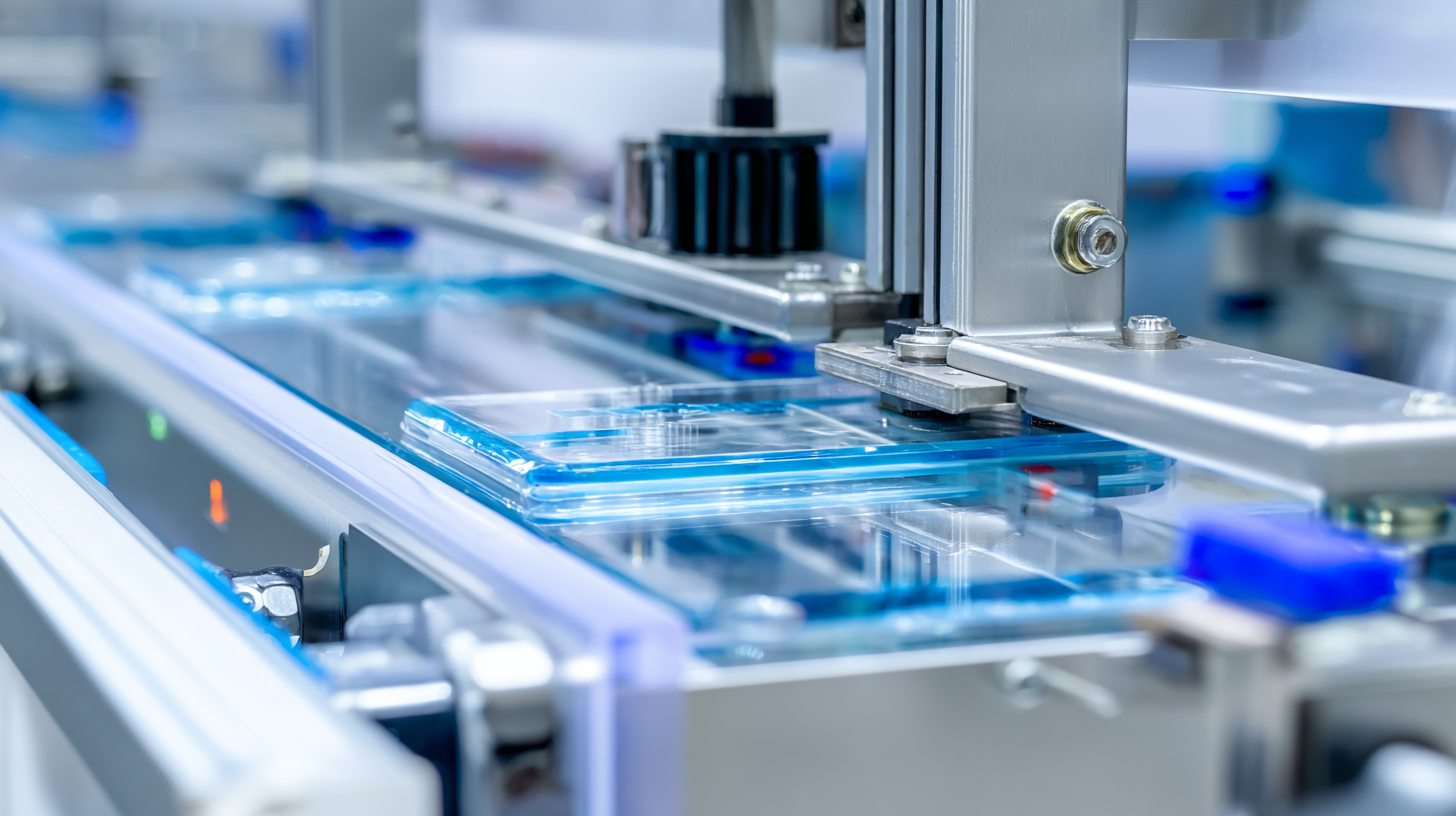

In the fast-paced packaging industry, efficiency and reliability are paramount, making the heat sealing machine an indispensable tool for manufacturers. As products are increasingly required to meet stringent quality standards while also being cost-effective, the role of a heat sealing machine becomes even more critical. This blog explores the real-world applications of these machines and highlights the challenges faced by businesses in the packaging sector.

From food products to medical supplies, heat sealing technology ensures product integrity and safety, yet companies encounter obstacles such as equipment maintenance and the need for versatile sealing methods. By examining top strategies for optimizing heat sealing processes, we aim to provide insight into how businesses can overcome these challenges and enhance their packaging operations, ultimately leading to improved customer satisfaction and sustainability in their practices.

Real World Applications of Heat Sealing Machines in Food Packaging and Preservation

Heat sealing machines play a crucial role in the food packaging industry, ensuring that products remain fresh and safe for consumption. These machines utilize heat to bond materials together, creating airtight seals that protect food from contaminants, moisture, and spoilage. For instance, in the production of frozen meals, heat sealing is essential to maintain the integrity of the packaging, preventing freezer burn and extending shelf life. This technology is also employed in packing snacks and perishable items, where quick and efficient sealing is needed to preserve the quality and flavor of the food.

Despite their effectiveness, the packaging industry faces challenges related to heat sealing processes. One significant issue is the variability in material compatibility; not all packaging materials seal equally well under the same conditions. Additionally, factors such as temperature control and sealing time can affect the strength of the seal. Manufacturers must continuously adapt and optimize their heat sealing machines to meet the diverse needs of food packaging while ensuring compliance with safety standards. As the demand for sustainable packaging grows, integrating eco-friendly materials into heat sealing processes also presents a new set of challenges that industry players must address.

Impact of Advanced Heat Sealing Technology on Reducing Packaging Waste

The advent of advanced heat sealing technology has significantly impacted the packaging industry, particularly in terms of reducing packaging waste. One critical aspect is the integrity of the seals created when flexible food packages are heat sealed. A recent review highlights that factors such as seal temperature, dwell time, and material properties play a crucial role in ensuring effective seals, which in turn minimize leaks and product spoilage. Improved seal performance contributes to sustainability by reducing the need for excess packaging materials, subsequently lowering environmental footprints.

Moreover, companies are increasingly adopting automated packaging solutions to enhance efficiency and reduce waste. For instance, the deployment of automated packing machines can optimize the creation of custom cardboard boxes, ensuring that only the necessary materials are used for each order. This not only addresses the issue of waste in packaging but also aligns with consumer expectations for sustainability.

According to industry analyses, the growing demand for eco-friendly packaging materials is prompting innovation, with natural plant fiber-based materials gaining traction as both a sustainable and functional alternative in various packaging applications. By leveraging these advanced technologies, the packaging industry is taking significant strides toward a more circular economy, where the focus is on waste reduction and responsible resource use.

Challenges in Achieving Consistent Sealing Quality Across Diverse Materials

The packaging industry faces increasing challenges in achieving consistent sealing quality, particularly when working with diverse materials. As businesses strive for innovation and sustainability, they often encounter difficulties related to material compatibility and the sealing process. For instance, studies have highlighted how variations in surface roughness and material properties can significantly impact the effectiveness of heat seals. In flexible food packaging, inconsistencies in seal integrity can lead to compromised product safety and shelf life.

The packaging industry faces increasing challenges in achieving consistent sealing quality, particularly when working with diverse materials. As businesses strive for innovation and sustainability, they often encounter difficulties related to material compatibility and the sealing process. For instance, studies have highlighted how variations in surface roughness and material properties can significantly impact the effectiveness of heat seals. In flexible food packaging, inconsistencies in seal integrity can lead to compromised product safety and shelf life.

To address these challenges, technological advancements in heat sealing methods have emerged. Research into different seal bar geometries has shown promising results in enhancing the sealability of materials, including thermoplastic films and paper-based substrates. By refining the heat sealing parameters, manufacturers can improve not only the quality of the seals but also the efficiency of the packaging process. Understanding the mechanisms behind heat sealing allows for better material selection and processing, ultimately leading to more reliable and effective packaging solutions.

The Role of Automation in Overcoming Labor Shortages in Packaging Operations

The packaging industry is undergoing a significant transformation, particularly in the face of ongoing labor shortages. Automation is emerging as a crucial solution, enabling businesses to maintain efficiency while mitigating the challenges posed by a dwindling workforce. Automated systems, including robotics and smart technologies, are increasingly being integrated into packaging operations, streamlining processes and enhancing productivity. With innovations such as Automated Guided Vehicles (AGVs) and robotic arms, companies can achieve greater precision in their packaging lines while reducing dependency on human labor.

As advancements in technology accelerate, the adoption of automation in packaging has shown promising results. For instance, companies are embracing AI and machine learning to optimize workflows and anticipate inventory needs, which is vital in managing supply chain complexities. The recent industry shifts highlight how automated solutions not only address immediate labor challenges but also pave the way for sustainable practices. By leveraging environmentally friendly materials alongside automated operations, businesses can meet growing consumer demand for sustainability while increasing output. This convergence of technology and sustainability is reshaping the future landscape of the packaging industry.

Real World Applications of Best Heat Sealing Machine and Challenges Faced in Packaging Industry - The Role of Automation in Overcoming Labor Shortages in Packaging Operations

| Application Area | Heat Sealing Machine Type | Key Benefits | Challenges Faced | Automation Role |

|---|---|---|---|---|

| Food Packaging | Continuous Band Sealer | Increased speed and efficiency | High initial cost | Automated controls reduce operator error |

| Pharmaceuticals | Pouch Sealer | Maintains sterility | Complex regulations | Automation ensures compliance with standards |

| Consumer Electronics | Vacuum Sealer | Protection from moisture | Need for skilled operators | Automated systems fill skills gap |

| Beverage Industry | Horizontal Sealer | High throughput | Downtime due to maintenance | Predictive maintenance by automation |

| Cosmetics | Tabletop Sealer | Flexibility for small batches | Labor-intensive process | Robotics assist in packaging operations |

Innovative Solutions for Enhancing Seal Integrity and Shelf Life of Products

In the rapidly evolving packaging industry, the integrity of seals plays a critical role in ensuring the shelf life and quality of products. Innovative sealing technologies are being developed to address challenges such as contamination and degradation, which can compromise food safety and prolong the usability of packaged goods. A primary focus is on enhancing the reliability of heat sealing machines, which guarantee a strong bond between packaging layers. These machines are being integrated with advanced monitoring systems that detect seal integrity in real-time, reducing the risk of leaks and spoilage.

Furthermore, the demand for smart packaging solutions is also shaping the future of the industry. These systems utilize sensors and indicators to provide consumers with information about the condition of the product inside, thus enhancing safety and maintaining quality standards. As the global market for various packaging materials, such as flexible and vacuum packaging, continues to expand—with projections showing significant growth by 2032—the emphasis on innovative sealing methods and materials becomes increasingly paramount. This convergence of technology and packaging aims to meet consumer expectations for longer shelf lives and optimal food safety.